We are your partner from design to manufacturing.

At DuroByte, we create high technology products from concept, starting with the design of the product and followed by the manufacturing of product components, assembly and testing.

Specialized in:

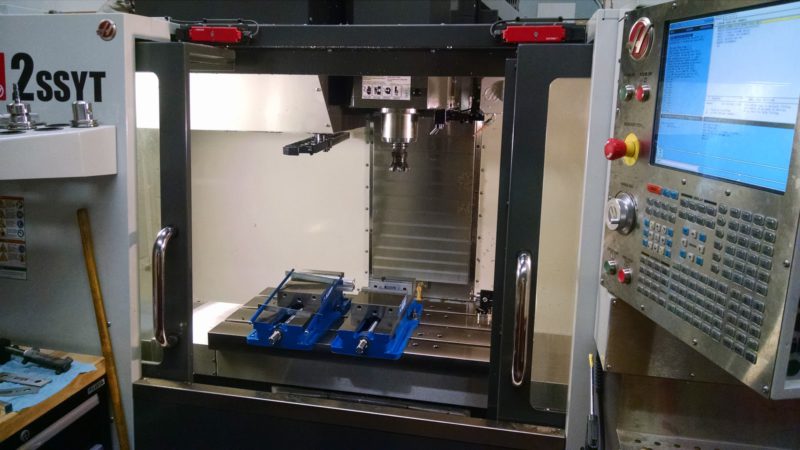

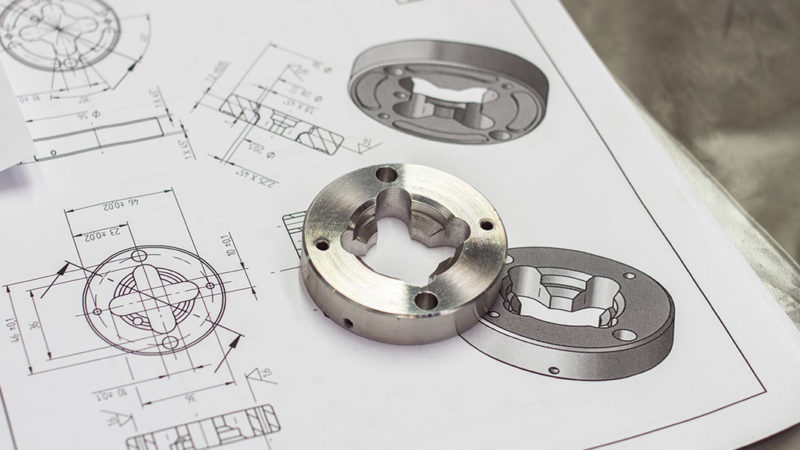

- Custom design and build

- Custom hardware

- Prototyping

- Low volume manufacturing

Applications:

- Custom details, brackets & fixtures

- Custom mechanical design

- Automotive parts and products